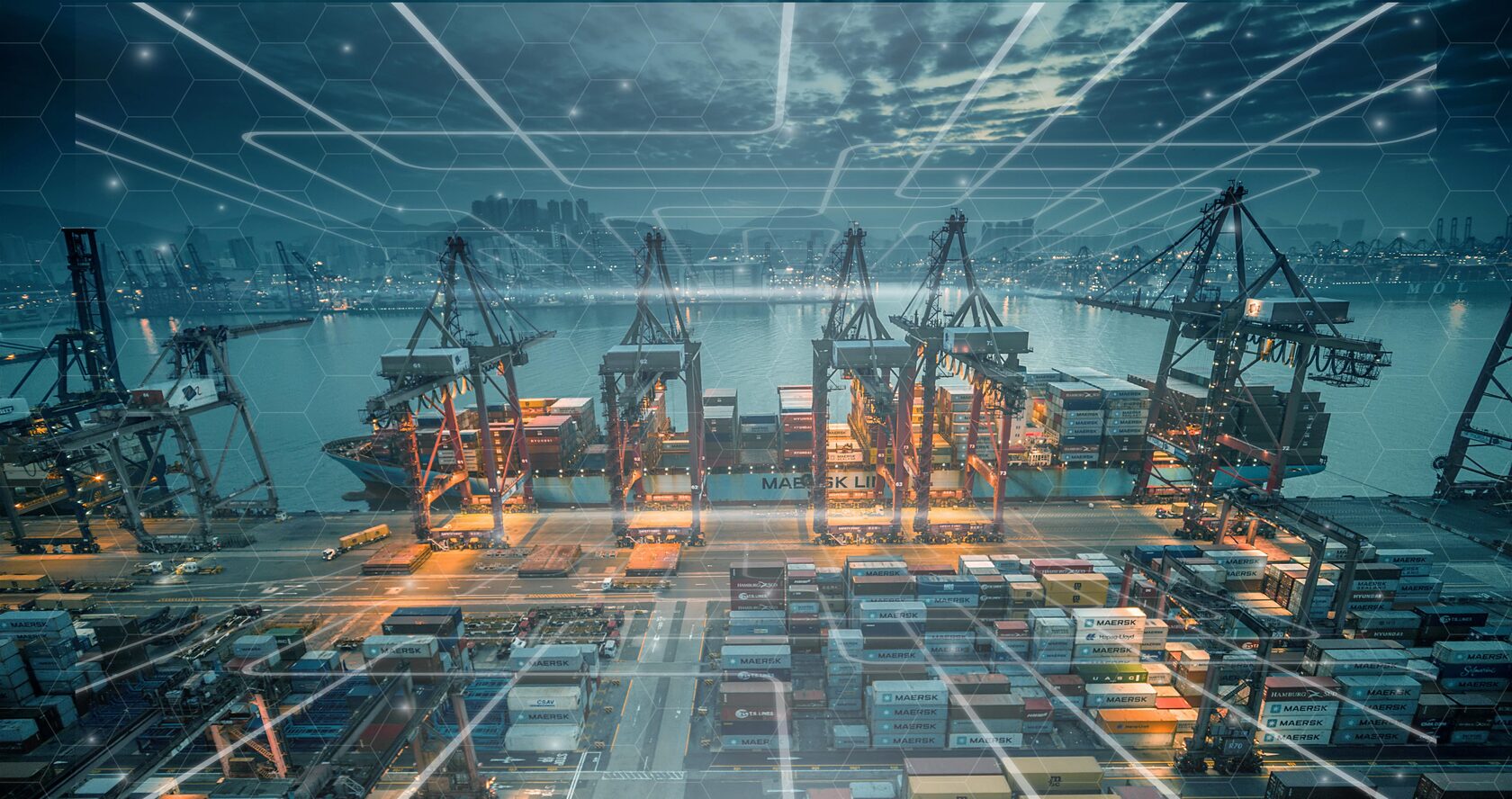

SMART SEAPORT

The Digital Twin of Seaport

Get more about Smarttwin system

SMART SEAPORT

The Digital Twin of Seaport

Get more about Smarttwin system

WHAT IS SMATTWIN ?

HOW TO REDUCE THE COST OF OPERATIONS AND IMPROVE EFFICIENCY ?

The Seaport has a lot of areas to store containers, bulk, Ro-Ro cargo

But how to find the right spot for cargo placement considering predefined limits for available storage, history of dwell time for every container, forecasted cargo arrival time, etc.?

Seaport is working with different transportation companies

But how to synchronize cargo operations with cargo delivery to\or from a terminal by trucks or railway?

Ships arrive every day

How to choose the right berth for each ship considering the type of cargo, assets availability for the cargo operations, storage capacity, vessel schedule, cost of operation and assigned laytime?

There are a lot of SMART management systems in the Seaport

Many details but how to see the whole picture?

SMARTTWIN SYSTEM

HOW IT WORKS

Always represent an existing operational object – from design proposal to system handover, the digital twin will reflect a real object

Represent the object's real-world state – provide data that describes the present and historical conditions of the object and external and internal processes

Models can expand into multiple realms: supply chain analysis can benefit from modelling warehouse operations, truck management system and weather conditions

Represent the object's real-world state – provide data that describes the present and historical conditions of the object and external and internal processes

Models can expand into multiple realms: supply chain analysis can benefit from modelling warehouse operations, truck management system and weather conditions

SYSTEM DESIGN

SMARTTWIN FEATURES

3D/2D model of the Seaport

User-friendly interface

Artificial Intelligence and Simulation Modeling

User-friendly interface

Artificial Intelligence and Simulation Modeling

WHY 3D

User friendly interface with natural view on virtual environment

User can observe on any object on the screen from different distance and angle

Zoom and rotation in 3 dimensions help to see everything from the best angle and distance without going on site

User can observe on any object on the screen from different distance and angle

Zoom and rotation in 3 dimensions help to see everything from the best angle and distance without going on site

USER FRIENDLY INTERFACE

The data collected from sub-systems is representing in Realistic 3D view

Real-time updates and reliable information

Direct access to any device or object at the Seaport

Monitoring and control on machinery

Different user profile settings

Objects and cargo search

Technological processes visualization

Visual planning of cargo placement in the storage zone

Real-time updates and reliable information

Direct access to any device or object at the Seaport

Monitoring and control on machinery

Different user profile settings

Objects and cargo search

Technological processes visualization

Visual planning of cargo placement in the storage zone

SmartTwin "rewind" feature

The REWIND feature allows:

- To restore the stage of all data systems in the Terminal (TOS, ERP, IoT Platforms, Fleet management, etc.) on any date in the past

- To show what was happening in the Terminal on any day in the past (operations, trucks and crane movements, cargo location, vessels, etc.)

- All data from different sources is consistent and time-stamped

- The data could be used for analysis, operation optimization, and anomalies detection

WHERE IS AI ?

The module uses self-learning AI algorithms, which are improving cargo operations, reducing the cost of them and collecting data for further analysis and operations optimization

WHERE IS AI ?

The module uses self-learning AI algorithms, which are improving cargo operations, reducing the cost of them and collecting data for further analysis and operations optimization

AI helps to detect and prevent accidents on the yard.

AI modules are working in the background and analyze Big Data coming from different sources.

AI helps in decision making for different user roles.

AI optimizes the cranes and truck management, berth allocation for vessels, cargo storage, container placement, manpower allocation, vessels movements, bunkering services, etc.

AI reduces the cost of operations and improves the time.

Simulation Modeling

The simulation model could be used for modeling of port operation including ships, internal and external trucks, berths, yard, warehouses, transit yard, ro-ro berths, cranes, forklifts, etc. in statistical-mathematical terms

Key benefits of the simulation modelling:

- statistics on cargo flows

- utilization of berths and equipment

- productivity indexes

- answer on "what if…" question

- helps in forecasting and planning resources

- improves productivity, machinery utilization, throughputs, eliminates bottlenecks in processes, reduce development and construction cost

BENEFITS OF SMARTTWIN

Digital Twin concept represents the convergence of the physical and the virtual world where every industrial product, operational process or asset will get a dynamic digital representation

Fast ROI for SmartTwin Deployment

Revenue Growth

Reduction of Operating Cost

Single high-level platform fulfilled with Big Data

3D visualization of assets and operations

Prediction of emergencies, testing reaction

AI for operation optimization

Simulation of processes, services and asset locations

Reducing human errors and improving productivity

Smart enterprise platform for real-time onsite or remote management

End-to-end integration with existing management systems

Saving on the cost of cargo moves, equipment maintenance, fuel consumption, time for the operation, rent cost, etc.

Improving terminal cargo throughput, berths usage, asset management, reducing dwell time for containers on the yard

USE CASES

HOW WE PROCESS THE DATA

9

years of research and development

4

seas

1 M+

real-time monitored objects

CONTACTS

INTELLECTIKA LLC

RUSSIA - MOSCOW

+ 7 (495) 215-11-80

UAE - DUBAI

+971 55 161 8657

port@ismarttwin.com

RUSSIA - MOSCOW

+ 7 (495) 215-11-80

UAE - DUBAI

+971 55 161 8657

port@ismarttwin.com